What Are The Different Types Of Guards Osha . 1910.214 — cooperage machinery [reserved] 1910.215 — abrasive wheel machinery. The regulation is broken down into these components: There are four general types of guards: What is the most common injury caused by working with machines unsafely? Best practices in implementing machine guarding in the workplace. Not all machines will need the same type of guards, but many will need a risk assessment to gauge the need for precautions. guards are barriers which prevent access to danger areas. One or more methods of machine guarding shall be provided to protect the operator and other employees. Choose the right type of guarding restraint. Regularly inspect and maintain guards. 1910.212 — general requirements for all machines. there are five (5) general types of machine safeguards that can be used to protect workers and personnel in the immediate. there are five methods of machine guarding: what are the 3 basic areas that need machine guarding? Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous.

from cecjlqly.blob.core.windows.net

what are the 3 basic areas that need machine guarding? Guards, devices, location or distance, and other awareness barriers. Choose the right type of guarding restraint. Regularly inspect and maintain guards. 1910.212 — general requirements for all machines. Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous. guards are barriers which prevent access to danger areas. osha machine guarding requirements. What is the most common injury caused by working with machines unsafely? There are four general types of guards:

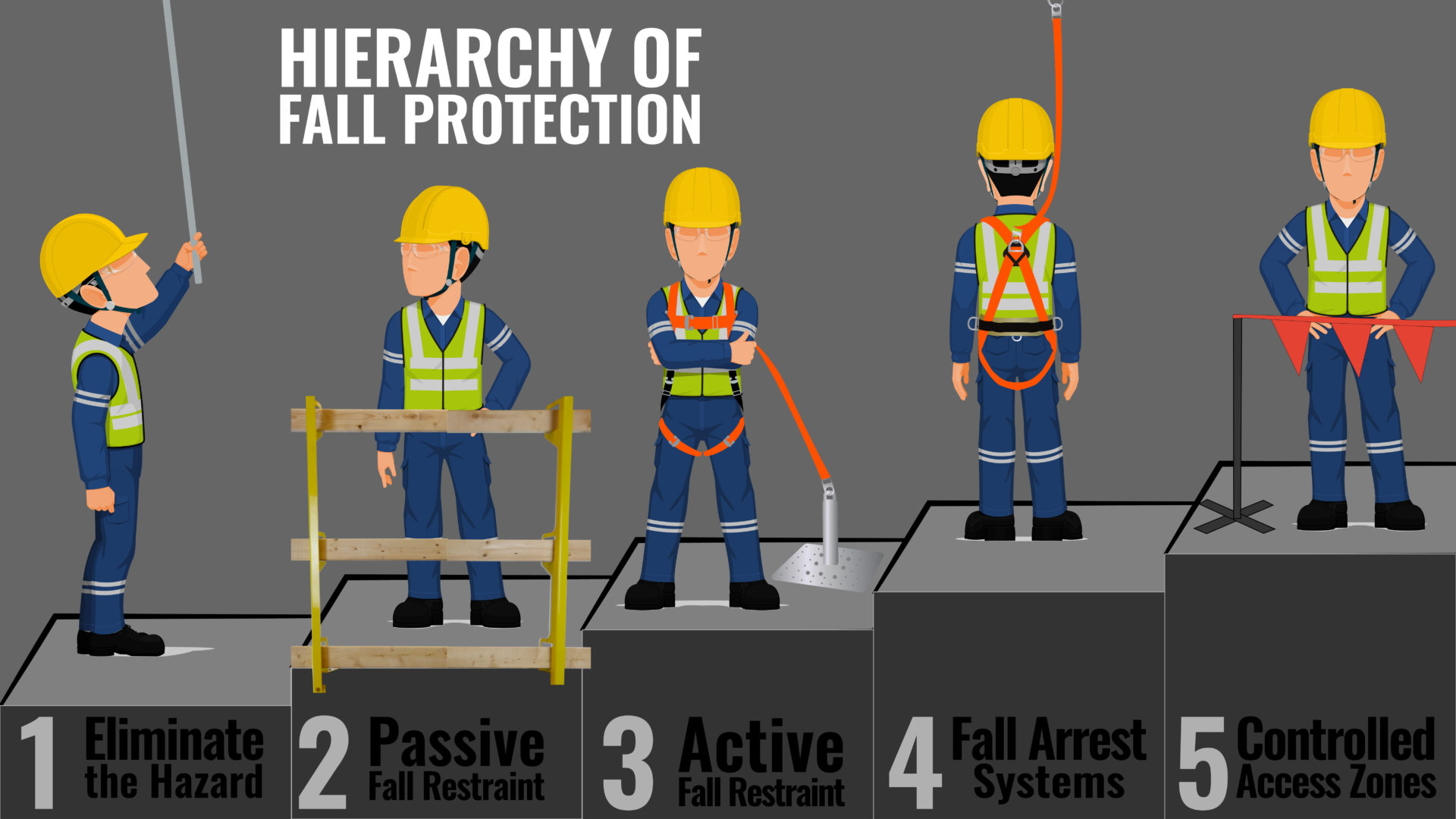

Osha Fall Protection Requirements at Robert Butler blog

What Are The Different Types Of Guards Osha 1910.214 — cooperage machinery [reserved] 1910.215 — abrasive wheel machinery. guards are barriers which prevent access to danger areas. 1910.212 — general requirements for all machines. There are four general types of guards: One or more methods of machine guarding shall be provided to protect the operator and other employees. osha machine guarding requirements. Choose the right type of guarding restraint. Best practices in implementing machine guarding in the workplace. Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous. Regularly inspect and maintain guards. osha’s requirements for machine guarding are found in 29 cfr 1910 subpart o, machinery and machine guarding. there are five methods of machine guarding: Not all machines will need the same type of guards, but many will need a risk assessment to gauge the need for precautions. The regulation is broken down into these components: what are the 3 basic areas that need machine guarding? What is the most common injury caused by working with machines unsafely?

From www.slideserve.com

PPT Machine Guarding PowerPoint Presentation, free download ID9720562 What Are The Different Types Of Guards Osha Regularly inspect and maintain guards. Choose the right type of guarding restraint. there are five methods of machine guarding: what are the 3 basic areas that need machine guarding? osha’s requirements for machine guarding are found in 29 cfr 1910 subpart o, machinery and machine guarding. What is the most common injury caused by working with machines. What Are The Different Types Of Guards Osha.

From www.iqsdirectory.com

Machine Guards Types Applications, Benefits, and Design What Are The Different Types Of Guards Osha what are the 3 basic areas that need machine guarding? What is the most common injury caused by working with machines unsafely? there are five (5) general types of machine safeguards that can be used to protect workers and personnel in the immediate. Guards, devices, location or distance, and other awareness barriers. Choose the right type of guarding. What Are The Different Types Of Guards Osha.

From www.thomasnet.com

OSHA Requirements for Machine Guarding What Are The Different Types Of Guards Osha Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous. Not all machines will need the same type of guards, but many will need a risk assessment to gauge the need for precautions. there are five (5) general types of machine safeguards that can be used to protect workers and personnel. What Are The Different Types Of Guards Osha.

From www.fallprotect.com

Understanding OSHA Requirements for Guardrail What Are The Different Types Of Guards Osha osha’s requirements for machine guarding are found in 29 cfr 1910 subpart o, machinery and machine guarding. Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous. The regulation is broken down into these components: guards are barriers which prevent access to danger areas. there are five methods of. What Are The Different Types Of Guards Osha.

From www.youtube.com

Types of Guards Fixed Guard Interlocking Guard Automatic Guard What Are The Different Types Of Guards Osha there are five (5) general types of machine safeguards that can be used to protect workers and personnel in the immediate. What is the most common injury caused by working with machines unsafely? The regulation is broken down into these components: Choose the right type of guarding restraint. Guards, devices, location or distance, and other awareness barriers. guards. What Are The Different Types Of Guards Osha.

From www.slideserve.com

PPT Machine Guarding PowerPoint Presentation, free download ID247693 What Are The Different Types Of Guards Osha Best practices in implementing machine guarding in the workplace. There are four general types of guards: there are five methods of machine guarding: 1910.212 — general requirements for all machines. osha machine guarding requirements. Regularly inspect and maintain guards. guards are barriers which prevent access to danger areas. What is the most common injury caused by working. What Are The Different Types Of Guards Osha.

From slideplayer.com

Preventing Amputations ppt download What Are The Different Types Of Guards Osha guards are barriers which prevent access to danger areas. Guards, devices, location or distance, and other awareness barriers. Choose the right type of guarding restraint. osha machine guarding requirements. One or more methods of machine guarding shall be provided to protect the operator and other employees. 1910.212 — general requirements for all machines. What is the most common. What Are The Different Types Of Guards Osha.

From www.slideserve.com

PPT Machine Guarding PowerPoint Presentation, free download ID6670306 What Are The Different Types Of Guards Osha Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous. 1910.214 — cooperage machinery [reserved] 1910.215 — abrasive wheel machinery. what are the 3 basic areas that need machine guarding? 1910.212 — general requirements for all machines. guards are barriers which prevent access to danger areas. there are five. What Are The Different Types Of Guards Osha.

From www.slideserve.com

PPT Machine Guarding PowerPoint Presentation, free download ID1769568 What Are The Different Types Of Guards Osha Guards, devices, location or distance, and other awareness barriers. What is the most common injury caused by working with machines unsafely? Choose the right type of guarding restraint. Regularly inspect and maintain guards. osha’s requirements for machine guarding are found in 29 cfr 1910 subpart o, machinery and machine guarding. Osha standards for machine guarding highlight three areas essential. What Are The Different Types Of Guards Osha.

From serinavillarreal.blogspot.com

which of the following is a type of machine safeguarding osha 10 What Are The Different Types Of Guards Osha One or more methods of machine guarding shall be provided to protect the operator and other employees. Choose the right type of guarding restraint. Guards, devices, location or distance, and other awareness barriers. guards are barriers which prevent access to danger areas. What is the most common injury caused by working with machines unsafely? osha machine guarding requirements.. What Are The Different Types Of Guards Osha.

From slideplayer.com

Preventing Amputations ppt download What Are The Different Types Of Guards Osha The regulation is broken down into these components: What is the most common injury caused by working with machines unsafely? guards are barriers which prevent access to danger areas. 1910.212 — general requirements for all machines. One or more methods of machine guarding shall be provided to protect the operator and other employees. osha machine guarding requirements. Not. What Are The Different Types Of Guards Osha.

From tvasherbrooke.com

6 Different Types of Security Guards And Their Roles (2022) What Are The Different Types Of Guards Osha One or more methods of machine guarding shall be provided to protect the operator and other employees. Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous. Guards, devices, location or distance, and other awareness barriers. There are four general types of guards: Choose the right type of guarding restraint. Not all. What Are The Different Types Of Guards Osha.

From www.slideserve.com

PPT MSHA Machine Guarding PowerPoint Presentation ID6750741 What Are The Different Types Of Guards Osha Regularly inspect and maintain guards. what are the 3 basic areas that need machine guarding? One or more methods of machine guarding shall be provided to protect the operator and other employees. Guards, devices, location or distance, and other awareness barriers. Osha standards for machine guarding highlight three areas essential to every piece of equipment that could be dangerous.. What Are The Different Types Of Guards Osha.

From www.youtube.com

OSHA Requirements for Guardrail YouTube What Are The Different Types Of Guards Osha One or more methods of machine guarding shall be provided to protect the operator and other employees. osha machine guarding requirements. What is the most common injury caused by working with machines unsafely? Regularly inspect and maintain guards. what are the 3 basic areas that need machine guarding? The regulation is broken down into these components: Best practices. What Are The Different Types Of Guards Osha.

From www.oshaeducationcenter.com

What Is an OSHA Card? Learn About the OSHA DOL Card What Are The Different Types Of Guards Osha What is the most common injury caused by working with machines unsafely? Guards, devices, location or distance, and other awareness barriers. Choose the right type of guarding restraint. Regularly inspect and maintain guards. The regulation is broken down into these components: what are the 3 basic areas that need machine guarding? there are five (5) general types of. What Are The Different Types Of Guards Osha.

From cecjlqly.blob.core.windows.net

Osha Fall Protection Requirements at Robert Butler blog What Are The Different Types Of Guards Osha 1910.212 — general requirements for all machines. Choose the right type of guarding restraint. osha’s requirements for machine guarding are found in 29 cfr 1910 subpart o, machinery and machine guarding. there are five (5) general types of machine safeguards that can be used to protect workers and personnel in the immediate. Osha standards for machine guarding highlight. What Are The Different Types Of Guards Osha.

From www.slideserve.com

PPT Machinery Safety PowerPoint Presentation, free download ID3129773 What Are The Different Types Of Guards Osha Regularly inspect and maintain guards. 1910.214 — cooperage machinery [reserved] 1910.215 — abrasive wheel machinery. there are five (5) general types of machine safeguards that can be used to protect workers and personnel in the immediate. 1910.212 — general requirements for all machines. Osha standards for machine guarding highlight three areas essential to every piece of equipment that could. What Are The Different Types Of Guards Osha.

From www.slideserve.com

PPT Machine Guarding 29 CFR 1910.211 to 1910.219 PowerPoint What Are The Different Types Of Guards Osha Choose the right type of guarding restraint. 1910.214 — cooperage machinery [reserved] 1910.215 — abrasive wheel machinery. guards are barriers which prevent access to danger areas. Not all machines will need the same type of guards, but many will need a risk assessment to gauge the need for precautions. there are five (5) general types of machine safeguards. What Are The Different Types Of Guards Osha.